DEVELOPMENT CONCEPT

Since its establishment, the company has been taking the road of professional development, and has established long-term cooperative relations with well-known domestic auto parts manufacturers. High trust!

AUTHORITY IN THE SPRING INDUSTRY.

We have a patent certificate for springs, and have the ability to develop products together with customers. Some products can provide free samples to customers.

ACHIEVE TO SUCCESS

We have 30 years of manufacturing and R&D experience. It has passed the IATF 16969 automotive quality management system, and has more than 200 sets of professional spring equipment, which can guarantee the quality.

After sales service

After-sale service and technical assistance: company provides after sales service and technical assistance as per customers' requirement and needs with response within 24 hours.

Related Products

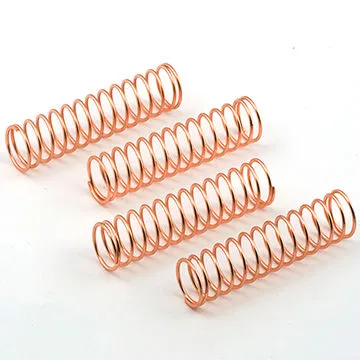

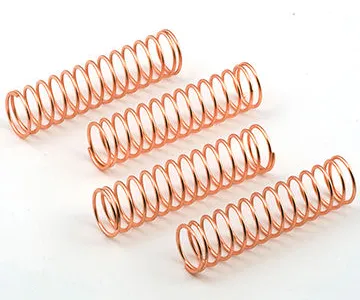

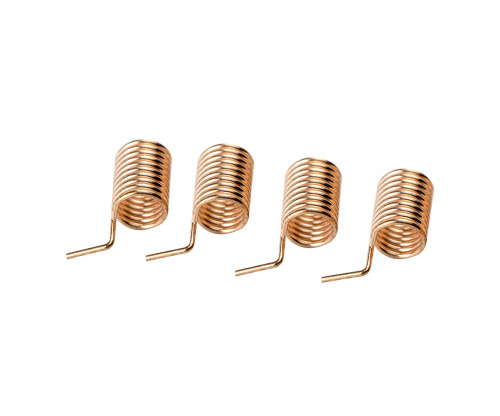

More items about copper spring

We Have The Best Solutions for Your Business

Wenzhou Heli Spring Manufacturing Co., Ltd. was founded in 1992. It is a high-quality spring manufacturing enterprise integrating design, production, sales and service. The current products include: compression springs, torsion springs, extension springs, auto parts springs, wire forming springs and spring sheets, etc.

Steel is a commonly used spring material.

The selection of spring materials must fully consider the use, importance and load nature, size, cycle characteristics, working temperature, surrounding medium and other conditions of use of the spring, as well as factors such as processing, heat treatment and economy, so as to make the selection result consistent with the actual situation. requirements match. Steel is a commonly used spring material. Non-ferrous metals can be used when the force is small and anti-corrosion, anti-magnetic and other characteristics are required. In addition, there are springs made of non-metallic materials, such as rubber, plastic, cork and air.

What are the most common springs?

Ordinary cylindrical copper alloy springs are relatively simple in the manufacturing process, and can be made into different styles according to the specific shape of the force, and the structure is simple, so the scope of application is relatively wide. The copper alloy spring is due to its manufacturing material It has a high elastic limit and impact toughness fatigue limit, and has good heat treatment performance, etc., so the selection of materials is relatively wide, among which copper alloys are more common.

How to choose the spring material correctly?

The choice of spring material should be determined according to the nature of the spring's load, stress state, stress level, working temperature, environmental medium, service life, requirements for electrical conductivity, process performance, material source and spring price.

When determining the shape and size of the material section, the series of sizes specified in the national standards and ministerial standards should be preferred, and the selection of non-standard series of materials should be avoided as much as possible.

Spring processing technology

Spring processing has cold rolling, hot rolling and other processing methods, and then it has to undergo a series of processing such as grinding, shot peening, heat treatment, setting, coating, packaging and other processes. Let's briefly introduce the heat treatment of the lower spring.

Heat treatment. Whether the steel is hot rolled or cold rolled, this process creates stress in the material. To relieve this stress and allow the steel to retain its characteristic elasticity, the spring must be heat treated by tempering. The springs are heated in an oven, held at the appropriate temperature for a predetermined time, and then allowed to cool slowly.

User Reviews

What users say about Heli Spring

Frequently Asked Question

Do you have any question?

Beryllium copper (BECU) is often used in spring clips and flat spring production because of its great strength. It yields the same spring force as carbon steel at a fraction of the thickness.

Beryllium copper spring is a mechanical part that uses elasticity to work. Parts made of elastic beryllium copper material deform under the action of external force, and return to the original shape after removing the external force. Generally made of C17200 beryllium copper.

Beryllium copper is a non-ferrous alloy used in springs, spring wire, load cells, and other parts that must retain their shape under repeated stress and strain. It has high electrical conductivity, and is used in low-current contacts for batteries and electrical connectors.

Copper alloy springs have good electrical conductivity, thermal conductivity, non-magnetism, and have good corrosion resistance and wear resistance, especially copper springs will not produce sparks when they are hit. Springs made of this material are ideal for use in marine, chemical and instrumentation and electrical industries.